For the conversion cost of various process such as Mixing, Tred, Bead, Inner, Chaffer, Calender, tyre building there are multiple excel files and Norms available offline based on that the costing team compute the conversion cost, this conversion cost has no co-relation with the current / latest or everyday cost of the Direct labour, Indirect labour, Machine cost, Power cost etc. These rates in excel

Then entire solution for the new product pricing will be carried out on the standard SAP feature of “ Base Planning Object” along with additional support from the systems costing mechanism and some custom reports that are already being developed for some other purpose.

The solutions for the new product pricing is as under:

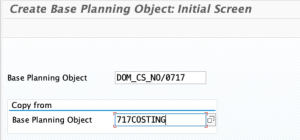

We can create the new costing specs. By copying the similar previous specs. So that all sorts of formulae and working can be re-used for the new pricing process.

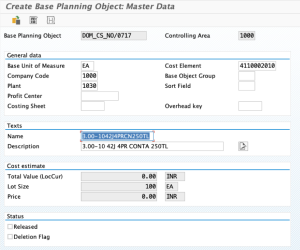

The new Specs. Name is DOM_CS_NO/0717. At the time of new product pricing there is no finished material code available in system for doing the costing or maintaining the BOM or Routing for the New Product Specs. So we need to carry out the costing without the FG material code.

In the following screen we will give the required details for the New Product Specs.

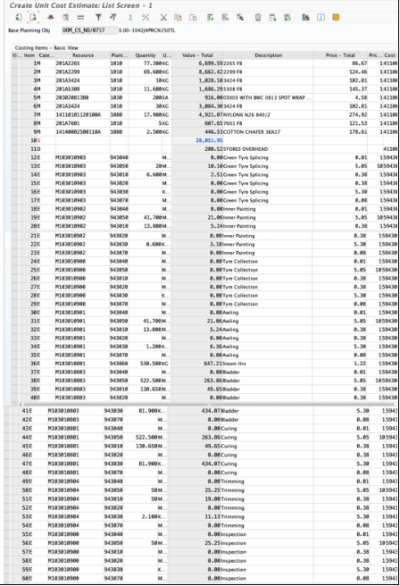

After this initial set-up for the new product specs. Then we need to plan the material cost, curing cost ,conversion cost , various overhead,

This costing is for the costing lot size of 100 tyres.

This data can be printed in documents and downloaded in Excel as well.

Following are the additional support required in the above costing model;

We can take this data and enter in the above costing sheet for new product pricing.

Fell free get in touch with us via phone or send us a message